Services

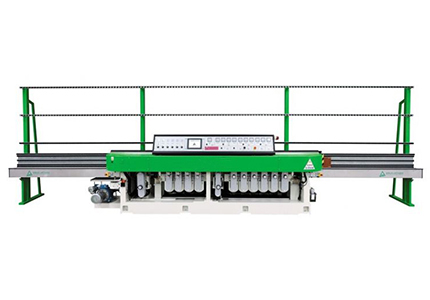

TNC Glass offers services including drilling, edging, notching, and custom cutting using advanced machinery. Our modern equipment ensures fast, precise, and beautifully finished products that meet every customer’s requirement.

AA Edge Polishing (Fine Edge Grinding / Rim Polishing) is the process of grinding and polishing the glass edges to achieve a smooth, glossy finish suitable for showcasing. This technique is ideal for furniture, tabletops, doors, windows, partitions, frameless doors, and display panels. The glass used for such applications is precisely edge-ground and polished to create clean, elegant lines.

This is the process of grinding the glass edges all around, creating beveled edges without polishing. The edges appear frosted and are suitable for installation in corners or for applications where the glass edge is not meant to be showcased.

This is the process of deburring glass edges using sandpaper, smoothing the top and bottom edges to prevent cuts during installation. It is suitable for framed installations or for general-purpose glass.

Bevel Grinding, width ½”–2”. In the case of double-layer beveling, each layer should not exceed 20 mm. This process grinds the glass surface to create a smooth, glossy finish, taking into account three key factors: the bevel width, the bevel angle, and the chamfer width. TNC Glass can achieve bevel widths up to 45 mm, and for double-layer beveling, each layer can be up to 20 mm wide.

Round Edge Grinding (Turtle Back Grinding) is the process of shaping glass edges into a smooth, half-round profile with polished finish. It is commonly used for furniture applications, such as table tops or shelving, where both aesthetic edge display and user safety are important.

Corner Bevel Grinding, 45°–90°, is the process of grinding glass edges for corner installations to add a distinctive touch to the piece. It is ideal for glass rooms or display cabinets. TNC Glass can grind corners at angles ranging from 45° to 90°.

TNC Glass can drill holes ranging from a minimum of 6 mm to a maximum of 100 mm, and notch sizes starting from 70 × 120 mm. These processes are suitable for accommodating various hardware and fittings.

Sandblasting is the process of etching the glass surface to create a frosted or matte finish, commonly used for decorative frameless panels, bathroom glass, or partition doors. This technique involves spraying specially selected sand onto the processed glass surface using compressed air. The texture, depth, and pattern of the frosted effect can be precisely controlled by adjusting the sand type and air pressure, allowing customization according to customer requirements.

The R value depends on the thickness of the glass. R value Glass thickness R 1000 5 , 6 มม. R 1500 5 , 6 , 8 , 10 มม. R 2000 5 , 6 , 8 , 10 , 12 มม. R 2500 5 , 6 , 8 , 10 , 12 , 15 มม. R 3000 5 , 6 , 8 , 10 , 12 , 19 มม. หมายเหตุ *ค่า R น้อย โค้งมาก

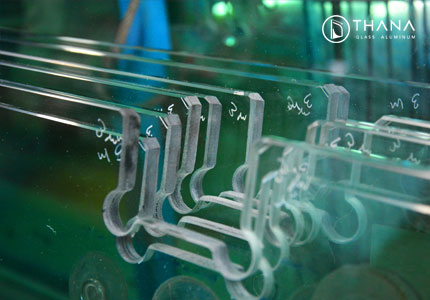

Custom Glass Cutting is the process of tracing patterns from plywood, paper, or fiberboard templates onto glass for precise cutting. This method is used for stair railings, guardrails, display cabinets, and various furniture applications.